These are the 2 styles of CV boot banding clamp tools, these are USA made and can be had for about $30 each or less if you shop around, you will also need a set of snap ring pliers, the convertable ones will do fine, or 2 flat head screw drivers.

This shows the inner CV cups you'll have to swap. Other than color, they are shaped differently, the BB (green one) is also larger on the stub shaft in diameter and length. This is why the BB inner cups are needed.

This is the other part that needs to change, the photo above shows why, the BB cup uses a smaller inner cv race than the wolvy, so you'll have to swap that onto the wolvy shafts as well. If you've never rebooted a CV joint, it's messy, but simple. Once the boot is opened up pull the outer cup snap ring. This allows the cup to be removed. Then the inner snap ring can be removed, this one holds the CV race to the shaft. Also of note Wolvy inner shaft and BB

inner shaft are same size/spline count and the snap rings inner change; however, the outer cup snap rings are smaller on the BB inner cups thou so don't mix them up, ask me how I know.

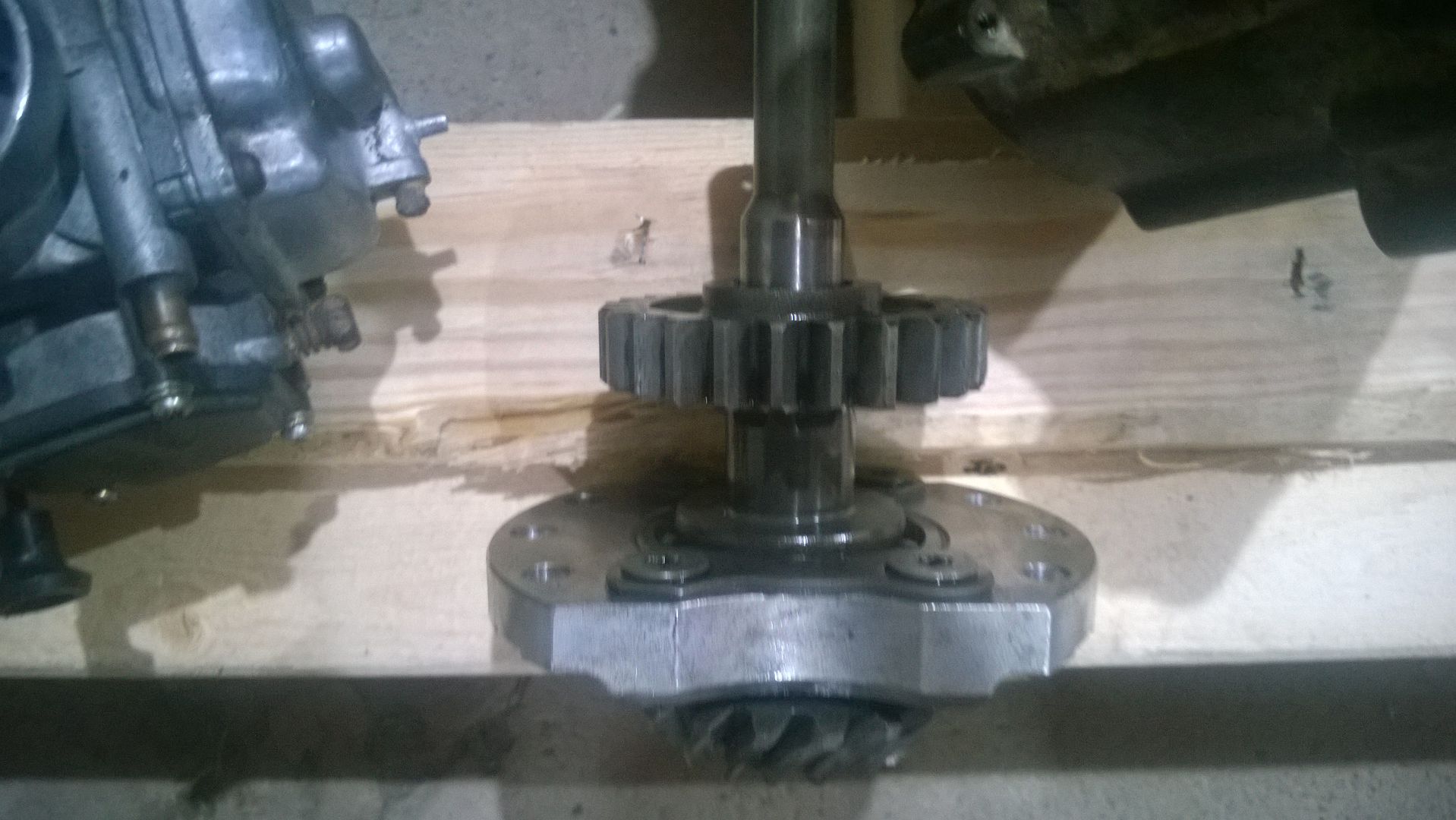

End result is this.

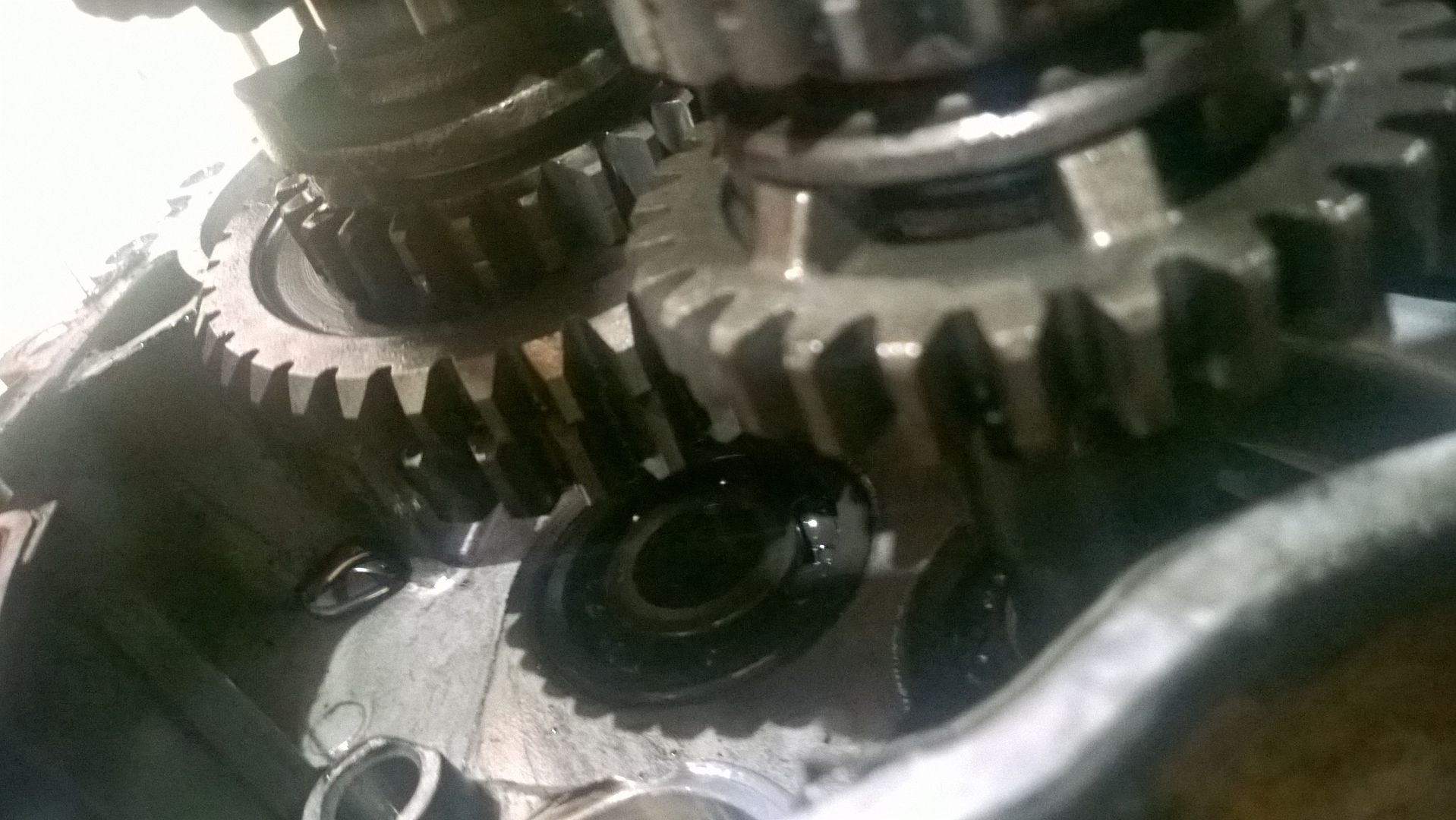

Here is the BB diff now installed on the wolvy.

Here is everything reinstalled, I still need to shorten the drive shaft, it measures 15.2mm in diameter, so I will make a sleeve out of some solid stock steel on a lathe, cut 1 3/4" out of the center of the front driveshaft.

stick the 2 ends into the sleeve and weld it up. You may be able to use a 02-06 BB front driveshaft, but I don't know if it would work. It is shorter than the full time 4x4 BB thou; however, I don't know if the wheel base is the same as the wolvy.:???: