You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Je 12.1 Compression Piston...

- Thread starter surftouch

- Start date

Help Support Yamaha Raptor 350 & Warrior Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

We have had members in the past with them and nobody had any complaints about them. With compression that high you will probably need to run a mix of 93 and race gas to make it run smoothly though. I'd never run any more than 11:1 compression in mine because it's not worth all the extra trouble for the little bit more power you can squeeze out with the higher compression.

deadaim

Well-Known Member

Id def.. go with some other mods to go with that piston.. Cam, HD valve springs oil cooler.. to bring it to its full potential

I have a few pics of the oil cooler stuff. Not as good as the ones that went with the tutorial, but it's the best I can come up with.

Big Bear adapter with stock shifter:

Big Bear adapter with custom shifter made from stock banshee shifter, note the oil seeping from the fittings because I didn't use enough thread tape (it takes a LOT of thread tape to seal them perfectly for some reason)

Hose routing (this is a modification I made to decrease the risk of the hose getting damaged. If you look closely at the fittings you can see that there are 2 hose clamps on each hose. One is holding the regular oil/trans hose on the barb fitting, and the other is holding the larger diameter heater hose down. I added a piece of larger hose as a sheathing over the smaller hose to protect it from trail debris and getting pinched by rocks. (I had a close call with mine and almost lost all my oil before I saw that the line got pinched by a rock)

Cooler mounting under hood, with plastic trimmed out to fit:

And this one has no real relevance but I felt like posting it:

Not sure what good this one will do either, but i'm bored, ok?

Big Bear adapter with stock shifter:

Big Bear adapter with custom shifter made from stock banshee shifter, note the oil seeping from the fittings because I didn't use enough thread tape (it takes a LOT of thread tape to seal them perfectly for some reason)

Hose routing (this is a modification I made to decrease the risk of the hose getting damaged. If you look closely at the fittings you can see that there are 2 hose clamps on each hose. One is holding the regular oil/trans hose on the barb fitting, and the other is holding the larger diameter heater hose down. I added a piece of larger hose as a sheathing over the smaller hose to protect it from trail debris and getting pinched by rocks. (I had a close call with mine and almost lost all my oil before I saw that the line got pinched by a rock)

Cooler mounting under hood, with plastic trimmed out to fit:

And this one has no real relevance but I felt like posting it:

Not sure what good this one will do either, but i'm bored, ok?

keglassg

Well-Known Member

haha that green and yellow one almost sits as low as mine! lmao

surftouch said:whats this big bear adapter???

It's detailed in the oil cooler tutorial, but this is the method of connecting the cooler to the oil system that's completely bolt-on with yamaha parts, instead of drilling and tapping the clutch cover. The part numbers should be listed in the tutorial or I can look them up and let you know what you need. Basically it's the cap with the fittings, the spacer, a washer, e-clip, spring, and valve disc, and o-ring (about $80 for all this brand new I think), and a couple brass fittings you can pick up at most hardware stores.

I like this method better for a couple reasons. Primarily, ease of installation. It doesn't involve taking off the clutch cover or any permenant modifications, just bolt the new parts on in place of the stock oil filter cap. It also has a built in bypass valve (that's what the valve disc, spring, washer, and e-clip are for) that will allow oil to continue flowing even if an oil line gets kinked and oil flow is restricted or stopped through the cooler. With the clutch cover tap method, the engine will be starved for oil if the line gets kinked for any reason.

Those that choose to use the clutch cover method have a couple reasons. One obvious one is that it's cheaper and you don't need to order parts, just pick up the fittings, drill bits, thread tap, and jb weld at a hardware store if it's not laying around in the garage already. This method also delivers the cooled oil to the bottom end of the engine first (i may have this backwards, maybe it's the big bear that cools the bottom end first).

Either way, it's up to you. Depending on what parts you need to buy, it might not be much cheaper to do the clutch cover method. Add up the cost of the clutch cover gasket and sealant, drill bit, thread tap, jb weld, and brass fittings. Plus if you sell the quad later, you can take the big bear setup off and sell it seperately like I did.

Yes, both of those things are true. A standard Hayden 401 cooler can drop the oil temp up to 40 degrees fahrenheit, and the oil will work to cool the vital components of the motor and reduce the overall temp. In addition, it also increases the oil capacity to almost 3 quarts. The oil doesn't break down as fast, and there's more oil for contaminants to dissipate into, so you have longer maintenance intervals because of it, and less wear on the engine.

A big benefit from the decreased temp is that it helps with transmission problems. Mine, as well as most other warriors, had a tendency to develop clutch drag when it got hot, which would make it impossible to find neutral when hot, and sometimes it wouldn't even come out of reverse when it was hot. The only time I could seem to find neutral was when I was racing it and shifting from 1st to 2nd, then it'd find neutral every time. The oil cooler really reduced those troubles.

A big benefit from the decreased temp is that it helps with transmission problems. Mine, as well as most other warriors, had a tendency to develop clutch drag when it got hot, which would make it impossible to find neutral when hot, and sometimes it wouldn't even come out of reverse when it was hot. The only time I could seem to find neutral was when I was racing it and shifting from 1st to 2nd, then it'd find neutral every time. The oil cooler really reduced those troubles.

dave76

Well-Known Member

I did the clutch cover style, as I listed to Mickey Dunlap of FST, he said this was the better method. Any oil cooler on a Warrior will be of a big help, the clutch cover style cools the main crank bearing and rod bearing first. The lines the way I ran them are way out of the way, it's possible to get them kinked, but hey I waould def. know it.

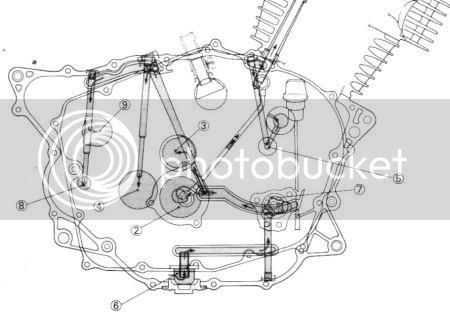

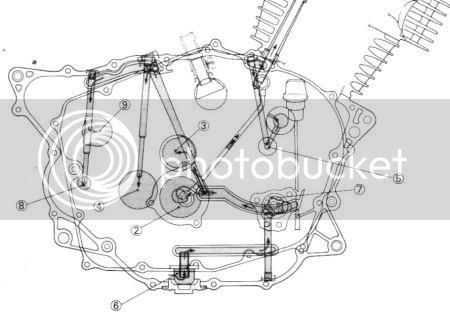

Here is the factory Yamaha oil circulation map

Here is the factory Yamaha oil circulation map

dswwarrior350

Well-Known Member

I have the 12:1 in mine. I cant really tell you how much of a gain i got from it alone seeing as i did a ton of mods at once. But even with the .430 cam it still has plenty of low-end power. It would be a wise choice to run a mix of 92 and race gas..... however as long as it wasnt like 80 degrees out i was able to get away with 94 octane pump gas. Its going to get hotter for sure... doing the oil cooler is a wise choice. I never did mine and have been fine for years, but i also keep it moving so it stays cool. AKA no mud pits and idling around.

My piston is made by Arias. I dont think they make pistons for the warrior anymore, but comparing it to other pistons ive seen its one of the nicest pieces i have ever held. I went .020 over to save the bore..... i'd like to re-ring it if i actually rode it and the rings were availible. It only been started 3 times in over a year and rode 2 of those times.

My piston is made by Arias. I dont think they make pistons for the warrior anymore, but comparing it to other pistons ive seen its one of the nicest pieces i have ever held. I went .020 over to save the bore..... i'd like to re-ring it if i actually rode it and the rings were availible. It only been started 3 times in over a year and rode 2 of those times.

jasonp

Well-Known Member

I will agree with that. Then when you are out on a trail good luck finding racing gas. Plus the **** isn't cheap.YamaRider said:We have had members in the past with them and nobody had any complaints about them. With compression that high you will probably need to run a mix of 93 and race gas to make it run smoothly though. I'd never run any more than 11:1 compression in mine because it's not worth all the extra trouble for the little bit more power you can squeeze out with the higher compression.

I have 10.5:1 piston in mine and she runs really hot. I've lowered the deck height to bring the compression up some more. I ride in some low speed areas and found I have to run a fan on the oil cooler. The engine gets really hot.